Typical restoration process for a Shelby Mustang.

When I undertake a full “nut and bolt” restoration, it will be completed to a concours Factory standard only. I will disassemble a car back to its bare shell, carefully noting and photographing all aspects of its construction and assembly.

Once stripped the shell is mounted on “rolling dollies” for ease of movement. It is then carefully shot-blast cleaned to remove all the old paint and finishes and expose any corrosion and previous accident damage.

Once clean the shell is located on an engineering bed-plate where it can be accurately postioned. This allows the body repairs and reconstruction to be undertaken whilst guaranteeing dimensional accuracy. The shells are invisibly repaired and reconstructed to match the Factory original pressings and type of welding. No plastic based body filler is used in any part of a finished shell. Once completed the repaired shell is re-blasted and then black zinc etch primed to protect against corrosion. From here the finished shell is fully painted.

This follows the original Factory process of panel sealer, sound deadener, red oxide primer, satin black and finally internal and external body colour.

The entire suspension, steering and braking systems are totally rebuilt and overhauled then detailed to perfection, ready for reassembly onto the finished shell.

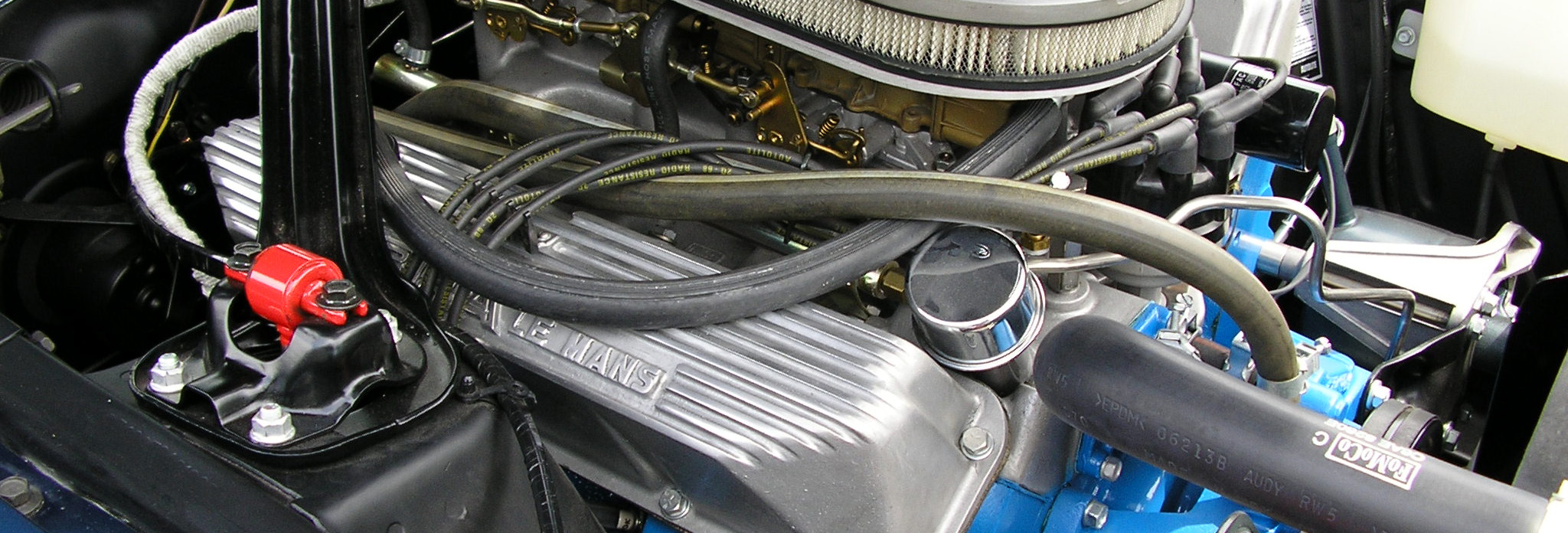

The engine is fully rebuilt to a balanced and blue-printed high performance standard and once complete is run on an engine dynomometer. This provides its finished horsepower and torque figures. Once finished it is detailed ready for refitment back into the car.

The gearbox and rear axles are fully rebuilt to the very exacting specifications, and again detailed ready for fitment back into the completed shell.

All the steel bracketry removed from the car during its disassembly is shot blast cleaned, zinc etch primed and powder coated black in a current Ford standard satin black.

These finishes exceed the original specification used on the parts when they were new, thus guaranteeing longevity of the restoration.

All the original nuts and bolts taken from the car are acid cleaned and zinc plated in the correct colours ready for reassembly.

No part in any of my fully restored vehicles is not correctly refinished and prepared.

Once complete, my aim is to give the owner close to a brand new vehicle as possible, one which looks and feels very authentic and a car that can and should be driven and enjoyed. I will ensure the vehicle is built as closely as possible to it original specification, not forgetting its previous, and often, very interesting history.

Fully completed vehicles are available for personal inspection.

Alongside my extensive full restoration work, I have been involved with the careful conservation and preservation of some very rare low mileage unrestored and original cars. This special work has been completed to ensure a safe and beautiful driving vehicle whilst not loosing any of the cars original patina.

Alan’s modest workshop is located some 6 miles outside of Newport Pagnell, in Buckinghamshire, England. Newport Pagnell still being the home to Aston Martins restoration head-quarters. Most of the restoration companies within this area are staffed by ex-Aston people and the quality of work produced is some of the finest available in England. These fantastically skilled people help me produce my cars to the utmost highest standards.